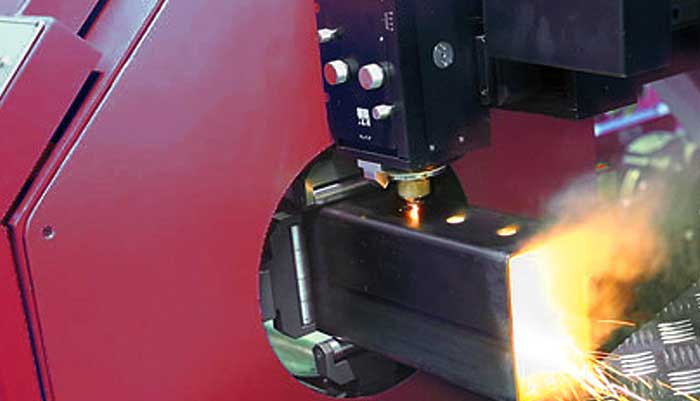

Fiber Laser Machine

Get exactly the right solution to your specific laser fabrication needs while delivering process quality and efficiency to metal and non-metal fabricating.

We haven't talked about cutting speed, you may have noticed. You can cut up to 500 inches per hour on a tube but it's not always possible. The main focus of laser tube cutting is how long it takes to load the tube, index it so that it's in the right spot for cutting, then pierce and slice it. Laser tube cutting machines have a slower cutting speed than they do with parts.